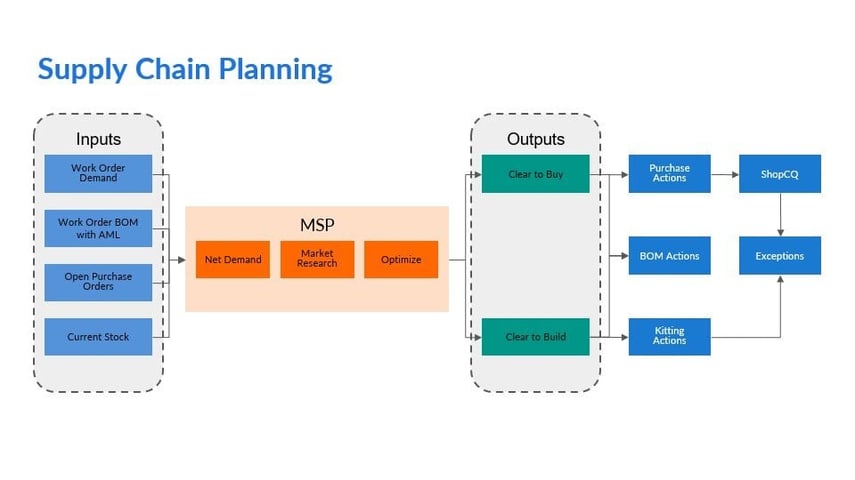

Material Supply Planner – Keep Production Supplied with Efficiency, Agility, and Minimal Inventory

With a holistic view of inventory, component supply and customer demand, identify what you can build when for optimized production, inventory management, and cash flow.

Cook up efficiency in your supply chain kitchen

Just like organizing ingredients to prepare a dinner recipe, Material Supply Planner (MSP) helps you optimize your production strategically by leveraging your current inventory, checking market availability and finding smart substitutions to align your supply chain with demand.

Using real-time data from your ERP system and the global component marketplace, we provide you with a blueprint to show you what to build now, what to buy today to build tomorrow, and how to swiftly adapt to demand changes and order.

-

What can I build now?

-

What can I buy today to build tomorrow?

-

How should I adjust my orders for the future?

-

What is the impact of a demand change?

Optimize production planning & break your logjam

Full View of Your Supply

Align Supply to Demand

Target Your Spend

Reduce Inventory and Excess

Maximize Cash Flow

Boosted Employee Morale

From bottleneck to agility: S and Y Industries' supply chain revamp with MSP

S and Y Industries, a premier EMS provider specializing in PCBA, encountered significant supply chain challenges, intensified by the global parts shortage. Implementing CalcuQuote's Material Supply Planner (MSP) revolutionized their procurement process, enhancing visibility across their supply chain in real-time. This transformation led to significant improvements in cash flow, operational scalability, and inventory management efficiency, while maintaining workforce levels. Additionally, it resulted in increased staff morale and satisfaction.

Explore CalcuQuote supply chain solutions

Each CalcuQuote software component is seamlessly connected to the same underlying robust CalcuQuote platform.

While each solution is highly effective on its own, the true transformation is unleashed when they are used together.

RFQ Management

Smart Purchasing

ShopCQ streamlines your procurement and allows you to purchase fast, smart, and efficiently.